Ceaseless challenge toward the top

High performance industrial gypsum

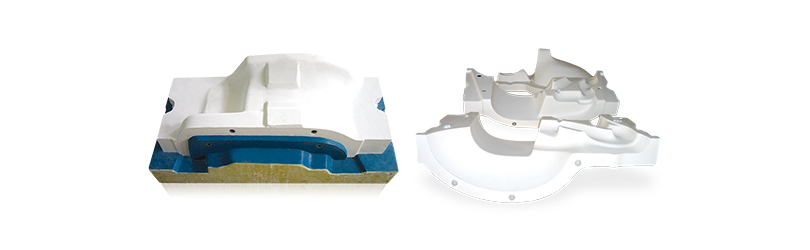

It is extra precision and high strength gypsum used for precision mold, inspection, copying and industrial purpose. It is mainly used for making and copying model, test models for mold making, replacement for wooden pattern metal plastic pattern and other cases for making plaster molds which demand intensity, hardness, measuring precision. Extra Hard Case Mold l For Extra Precision Mold Producing l For Molding Shrink rate Correction I For Non Ferrous Metal Casting

| Product Number | Gemstone N-2000 | Gemstone N-1000 | |

|---|---|---|---|

| Characteristic/Purpose |

Large Sized Precision Modeling Low expansion, High Strength, High Surface Strength |

Small Sized Precision Modeling High Strength, Low Expansion, High Surface Strength |

|

| Standard Mixing ratio(%) | 28 | 28 | |

| Beg Influx(min) | 15 | 13 | |

| Start Setting(min) | 25 | 18 | |

| Termination(min) | 60 | 50 | |

| Expansion At Termination(min) | 0.15 | 0.15 | |

| Compressive Strength | Wet(kgㆍf/㎠) | - | - |

| Dry(kgㆍf/㎠) | 700 | 600 | |

| Product Number | L-13 | L-11 | |

|---|---|---|---|

| Characteristic/Purpose | This is the most commonly used plaster breed and is used for molds and also lamination. | Hardening Time is long, there is very little expansion and thus is commonly used for molds with larger models. | |

| Standard Mixing ratio(%) | 42 | 43 | |

| Beg Influx(min) | 5-15 | 5-10 | |

| Start Setting(min) | 15 | 30 | |

| Termination(min) | 90 | 120 | |

| Expansion At Termination(min) | 0.015 | 0.015 | |

| Compressive Strength | Wet(kgㆍf/㎠) | 130 | 110 |

| Dry(kgㆍf/㎠) | 300 | 280 | |

The plaster slurry of L-13 is put inside by increasing its viscosity as time passes (liquidity decreased) > coagulation > It is coagulated in order of hardness and begins to expand and generate heat following the order.

| Product Number | Ω - 8 | Ω - 10 | Ω - 12 | Ω - 20 | |

|---|---|---|---|---|---|

| Characteristic/Purpose | Ideal for correcting the contraction of a resin mold | Representative for correcting a zinc mold | Ideal for correcting the contraction rate of zinc, aluminum, and light synthetic metallic molds | Ideal for correcting the contraction rate of general metallic molds | |

| Standard Mixing ratio(%) | 35 | 35 | 35 | 35 | |

| Beg Influx(min) | 8 | 8 | 8 | 8 | |

| Start Setting(min) | 15 | 15 | 15 | 15 | |

| Termination(min) | 60 | 60 | 70 | 80 | |

| Expansion At Termination(min) | 0.80 | 1.00 | 1.20 | 2.00 | |

| Compressive Strength | Wet(kgㆍf/㎠) | 190 | 180 | 160 | 200 |

| Dry(kgㆍf/㎠) | 270 | 260 | 240 | 200 | |

Plasters belonging to Ω category have big cooling expansion (0.5~2.0%) which cannot be seen in the existing burnt plaster by processing the burnt plaster with high intensity in a special way. They are used for making expansion models expansion molds which are to correct the solidifying contraction of metals or synthetic resins. The expansion size of Ω plasters varies according to the shape and material of a model, size of a model and water temperature and atmospheric temperature depending on seasons, it is recommended to order and production after consultation.

How to Use| Stirring Time | Stirring Efficiency | Hardening Time | Expansion Rate |

|---|---|---|---|

| Shorter | Longer | Lower | |

| Shorter | Quicker | Higher | |

| Lower | Quicker | Higher | |

| Higher | Longer | Lower |

| Product Number | C-2 | |

|---|---|---|

| Characteristic/Purpose | Tire mold, light alloy mold, good lnbrication of casting and size | |

| Percentage of Water(%) | 45-47 | |

| Pattern Extraction Time(min) | 50-60 | |

| Expansion At Termination MAX(%) | 0.25 | |

| Water Strength | Tensile strength(kgㆍf/㎠) | 10 |

| Compression(kgㆍf/㎠) | 30 | |